-

B-502, Twin Arcade,

Military Road, Marol,

Andheri(East),

Mumbai-400059,India

-

+91 81041 65398 / 022 47835474

-

Continuous leadership in advanced technology

Nissei Industry Corporation – Toyama, Japan established in 1979, is a leader in Japan and the world for Vertical and Horizontal Double Disc Grinders for many years.

In the last few years the demand for high quality industrial & consumer products has increased dramatically. Nissei has been assisting manufacturers in meeting that demand, by supplying them with precise double disc surface grinding machines that reflect Nissei's state-of-art technology. Nissei’s innovative approach to grinding machine technology has made it possible for them to develop machines with superior performance, simple operating commands and improved functions. Also Nissei's unique approach to customer service, which emphasizes consultation and dialogue, enables them to custom-make machinery that fits any specifications. In anticipation of increased demand for automated production systems, Nissei has developed grinding machines for installation on automated production lines.

- Nissei originally developed the World’s first “Vertical Double Disc Grinder” to compensate for lack of rigidity that is inherent in the design of Horizontal Double Disc Grinders.

- Nissei’s history shows how it developed the first grinding and super finishing combination machine and also “Double Disc Grinder” for Ultra-Thin parts (0.3 mm thick).

- World’s largest Vertical Double Disc Grinder V-10 TH was custom developed by Nissei for one of their customers.

- Nissei further developed “H series” High Rigidity Horizontal Double Disc Grinder which adopted quill type main spindles built in box framed bed.

- Nissei has been and will continue to do the best to respond customer’s requirements with new techniques & solutions.

Nissei’s V, VP, VPD etc. series are mounted on a vertical spindle, which allows greater accuracy in thickness. The grinding wheels’ contact with the work piece is always constant and grinding pressure is evenly distributed over the work piece surface. Several unique & patented features like box frame structure, quill sleeve main spindle, carrier hinged system, backlash elimination system etc. makes Nissei machines very special.

“Double Disc Grinding” maintains an extremely high level of stock removal for grinding and the forces present are correspondingly high.The Double Disc Grinders manufactured by Nissei have the highest standards on rigidity, technology and precision compared to others in the Double Disc Grinder / Duplex Grinder industry. Since its establishment in 1979, Nissei has been chasing pioneering technologies.

Few of the components which can be ground & process on Nissei machines are, Piston Rings, Bearings, Brake Disc, Brake Rotors, Oil Pump parts, CVT Parts, Connecting Rods, Valve Plates, Clutch Plates, Ferrite components, Shims & Washers, Ceramic components etc.

Features of the Nissei Double Disc Grinding Machines:

*Hover the mouse on proudct images to view details.

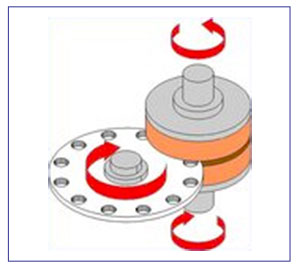

Double Disc Grinding - Machining Principle

Nissei Machine Features

V-5C Carrier Hinge Lock Opened for Ease of Access to Grinding Area

V-5PD For Grinding Two Wheeler Brake Discs

V-570PDR for Grinding 4-Wheeler Brake Rotors

V-7C for Piston Rings

Description of Nissei Machines

Sample Components Ground on Nissei Machines

Sample Components Ground on Nissei Machines:

Following are some of the feeding systems offered:

- Rotary Carrier

- Rotary Carrier with Belt Clamping

- Grinding Wheel Infeed & Oscillation

- Grinding Wheel Infeed & Workdrive

- Throughfeed / Thrufeed

- Gun Feed

Nissei also offers various type of automatic loading & unloading systems for its machines.

All the systems are designed & developed by Nissei in-house.

SKB's experienced Personnel are equipped to provide sales, after sales and technical support to customers.

Some of the best and well known users of Nissei machines in India for over many years...: NBC Bearings, Koyo Bearings, Nachi Bearings, Federal Mogul Group, India Piston Group, Endurance Technologies, Brembo, Shriram Pistons & Rings, Yutaka, Honda, Etc.