-

B-502, Twin Arcade,

Military Road, Marol,

Andheri(East),

Mumbai-400059,India

-

+91 81041 65398 / 022 47835474

-

IMM Maschinenbau GmbH – The Partner for Your Success

IMM Maschinenbau is a leading manufacturer of belt grinding and polishing equipment for surface processing with more than 60 years experience. Solutions range from polishing machines to manufacturing systems for the Power Generation, Aerospace, Oil & Gas, Automotive, Extrusion Screws, Kitchen sink & sanitary and Medical industry.

Through 50-year research on grinding and polishing technology, today IMM has been playing a leading role on manufacturing CNC grinding and polishing machines. IMM machines possess grinding, polishing and de-burring functions, and are very suitable for machining complex part for aviation and aerospace, turbine machinery and auto part manufacturing industries on the request to achieve high-precision and superior surface quality.

We, S K B Machine Tools, are the Sole Representative agency house for Sales and Service for IMM Machinenbau GmbH in India.

IMM Grinding and Polishing Machines are broadly employed in the following fields:

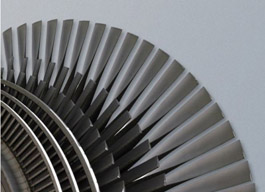

Turbine Blade Polishing

IMM machine models MTS & SPE are a standard in the manufacturing line of turbine blades for Power Generation & Aerospace industries.

MTS & SPE are 6 Axis CNC Turbine Blade Grinding / Polishing Machines for concave, convex, Leading Edge & Trailing Edge.

Usual blade length for the MTS machine is upto max. 1800mm or more as required with a max rotational dia of 800mm.

Usual blade length for SPE machine is upto max. 300mm. ( can be to 450 mm depending on blade pofile )

The following are few of the advantages of using IMM Turbine Blade Grinding Machine:

Some of the most well known users of IMM includes

IMM are specialists in Turbine blade finishing‐for aviation, power turbines and for such high end applications. The same technology is used in all their machines.

*Hover the mouse on proudct images to view details.

MTS Turbine Blade Polishing / Grinding Machine

MTS in Action

Blades Finished on MTS Machine (Surface Finish Ra 0.2 or even better possible)

SPE Turbine Blade Polishing / Grinding Machine

SPE in Action

Blade finshed on SPE machine

( LH milled profile with 5 mm Milling pitch and RH finsihed on SPE Machine with Surface Finish Ra= 0.2 )

KWS Machine for Polishing Crankshafts & Rotors

KWS in Action Finishing Crankshaft, Extrusion screws and oil drilling screws

Industries Served

IMM offers Grinding, Polishing & Super finishing machines for a number of applications.

Few of the machines offered by IMM are as follows: